GFUN invests considerable resources in R&D each year, not only to develop new products and technologies for the coming season, but also to explore prospective manufacturing processes in the laboratory before broader application. The R&D Center is an indispensable driver of growth behind our marketing, business, and new product launch.

R&D Focus

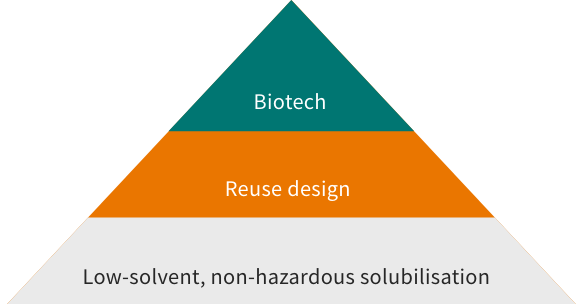

Corporate Strategy

GFUN invested in an industry-leading polymer laboratory and is now working closely with chemical suppliers to develop patented membrane and coating materials and technologies.

We have been awarded a number of international environmental certifications, including: Swiss bluesign®, Swiss STANDARD 100 by OEKO-TEX®, US Global Recycled Standard (GRS), US Higg Materials Sustainability Index (Higg MSI), and EU Registration, Evaluation, Authorisation and Restriction of Chemicals (REACH).

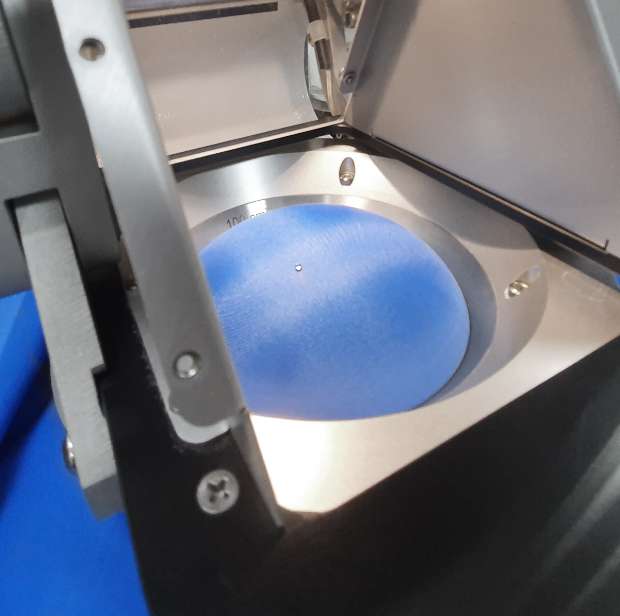

Functional Product Processing Laboratory Equipment

Experimental textile coating equipment

Experimental laminating equipment

Experimental calendering equipment

——

Functional Textile Testing Laboratory Equipment

Moisture permeability testing equipment

Water resistance testing equipment

Water wash testing equipment

We have transcended the boundaries of traditional recycling. We started by working with commonly recycled textile and apparel industry materials, such as PET bottles as well as garment and textile production waste, but are now working with the technology industry to jointly develop high-tech waste recycling.

GFUN has the technology to recycle waste PU from electronic materials factories into hydrophilic, non-porous functional membranes with 27 to 40% of recycled PU content, waterproof rating greater than 15,000mm (JIS 1092 B), and moisture permeability rating of more than 70,000mm (JIS 1099 B1). Waterproof, moisture-permeable fabrics made with this membrane have superior flexibility and texture compared to competitors. Furthermore, the membrane can be easily adapted to other fabrics or waterproofing processes to offer consumers a wider range of options to choose from for perfect protection.

GFUN has developed eco-friendly products that utilize significantly fewer solvents, less harmful and less polluting solvents, or completely solvent-free process technologies such as water-based adhesives that are dimethylformamide (DMF)-free and toluene-free. Our goal is to develop products that slow global warming, reduce chemical hazards, and improve the health and well-being of everyone, as well as consistently perform better than traditional products.

GFUN leverages its core capabilities to develop protective clothing and isolation clothing that meet international standards.

Our isolation clothing is compliant with CNS 14798 P1, P2 standards.

Our protective clothing is compliant with CNS 14798 P3 standard.

Our products are water-resistant at up to 1400 mmH2O, moisture permeable at up to 1500g/m2 .24hr.