Traditional waterproof and breathable materials mainly come from PU, TPU, and other polymer materials. While highly-waterproof, these materials cannot be recycled through depolymerization. To create a recyclable material that has both the water resistance and moisture permeability needed, the functionality has to be derived from a single polymer. At GFUN, we can combine waterproof, breathable, and recyclable, all into one material.

Face: 100% polyester

Membrane: TPEE membrane

Back: 100% polyester

GFUNRGTR-20 has a membrane thickness of 20μm and is made of 52% recycled polyester.

Water-resistance>10,000mmH₂O (JIS 1092 B)

Moisture permeability>10,000g/m².D (JIS1099 B1)

Flexible and comfortable

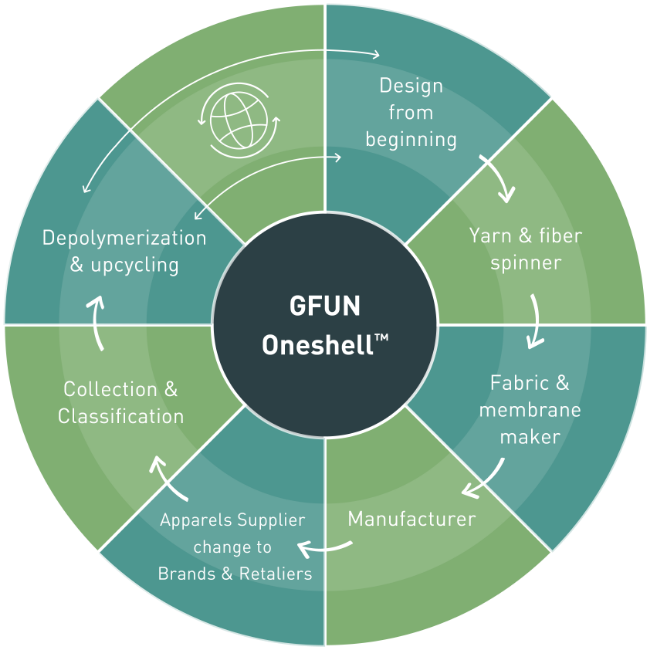

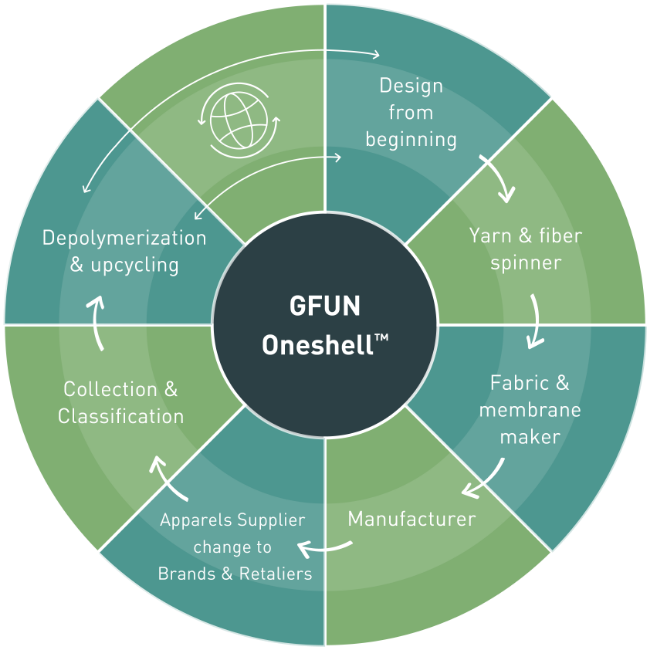

ONESHELL™ is built around the philosophy that simple is beautiful. We have developed a mono-material method of manufacturing a wide range of fabrics, including 2 and 3-layer waterproof and breathable fabrics, from one single polymer.

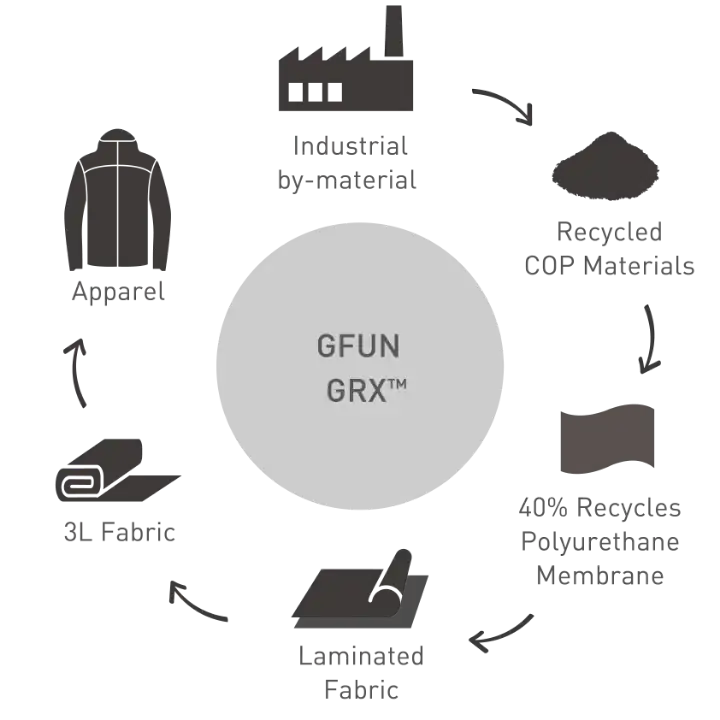

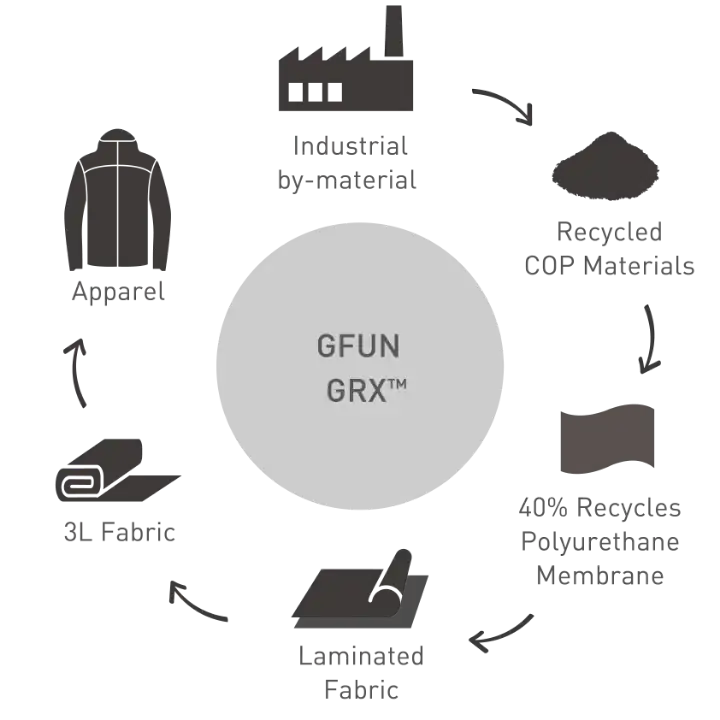

We partnered with a high-end lens supplier in Taiwan to recycle polymer scraps from their manufacturing process into a synthetic coating material and waterproof polyurethane (PU) membrane. We call this technology Green Recycle eXtreme, GRX™. GFUN GRX™ PU contains 27% recycled materials from other industries. The material is in the process of acquiring international patents and has already obtained international GRS certification. International brands can apply for a GRS Transaction Certificate (TC) to enhance the added value of their products.

GRX™ provide 27-40%

Contents from recycled materials.

GFUN uses the following as our primary biomass materials to help reduce our overall carbon footprint.

Recycled Coffee Oil – Airman®

PU – 25% Bio/Bio Latex mixed

PU – 50% Bio / 50% PU