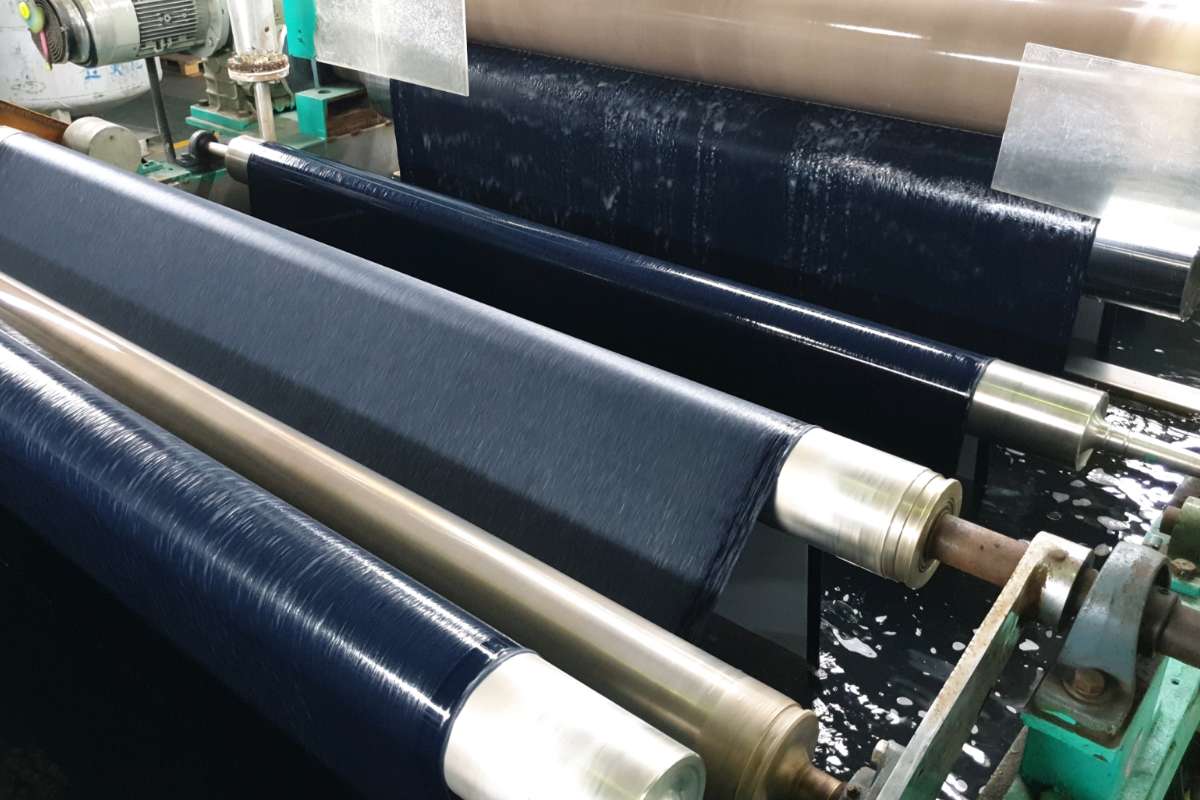

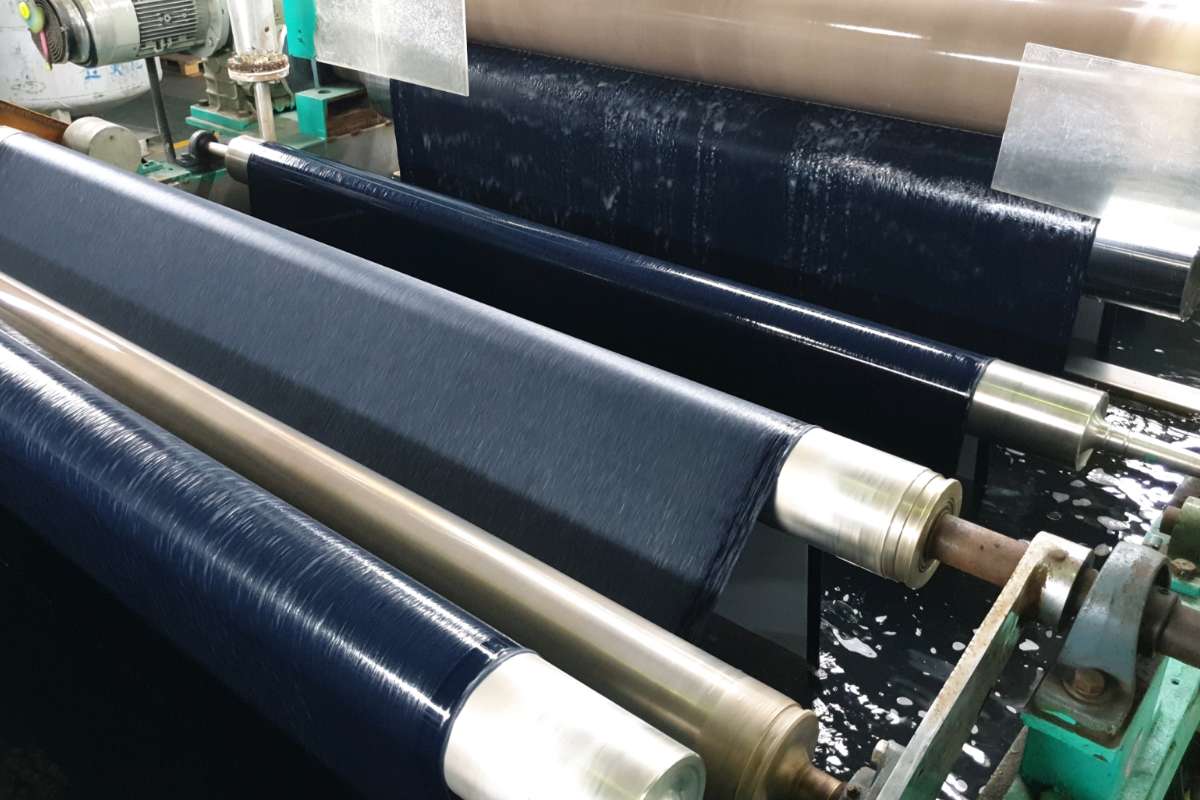

GFUN is one of the few manufacturers equipped with both technologies. We produce 36 million yards of wet microporous coating every year. It dries easily and has A1-compliant water vapor permeability, making it suitable for mountaineering, skiing, and workwear.

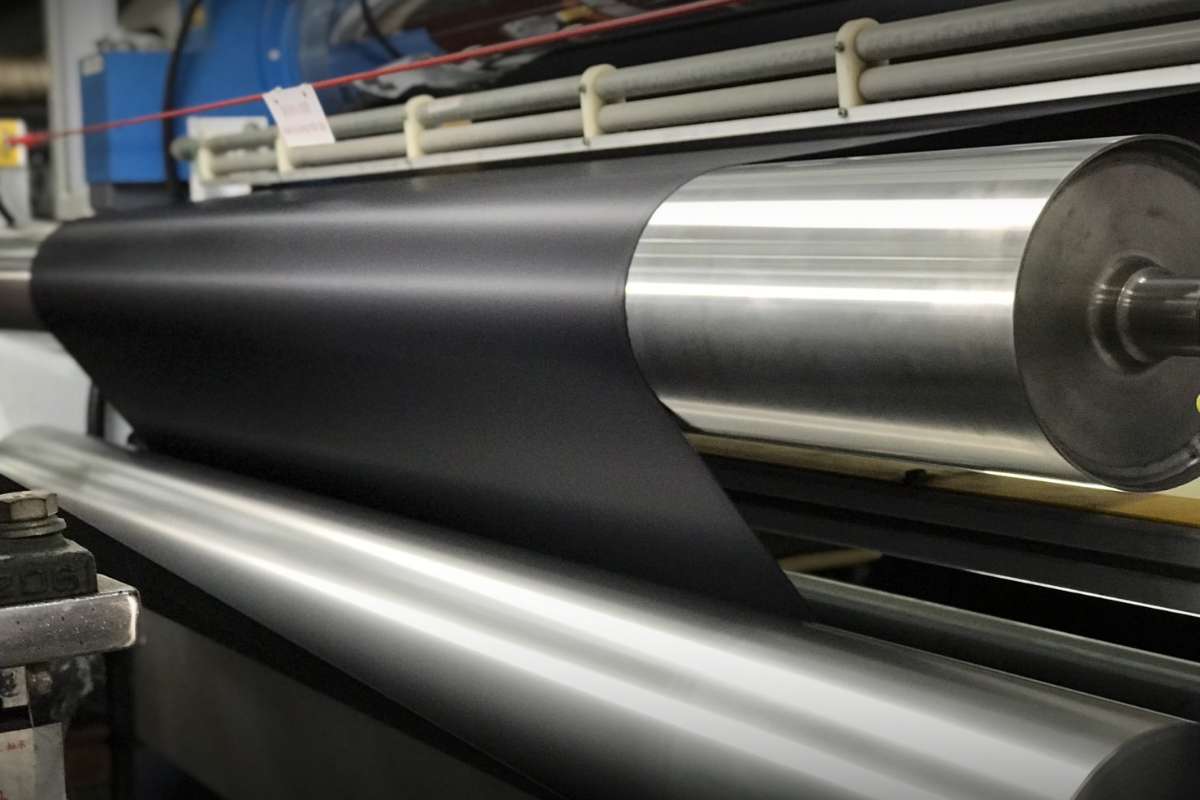

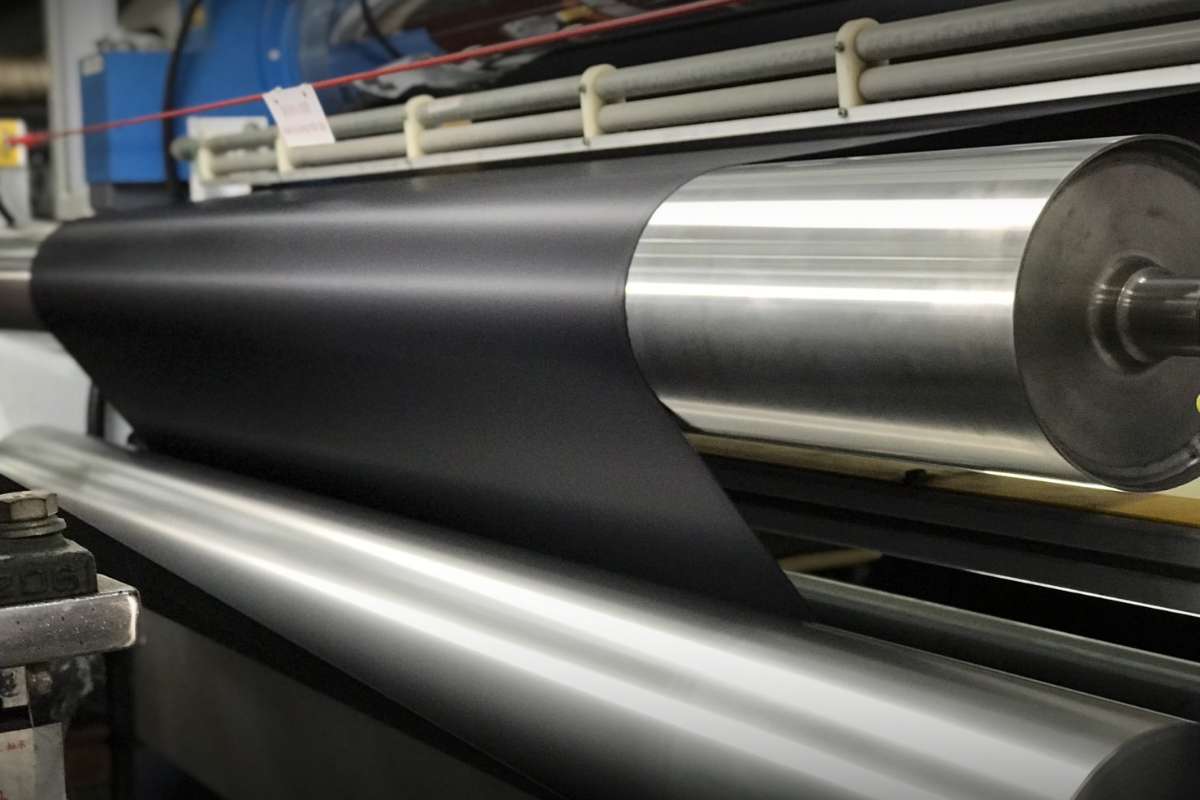

GFUN membranes are used internally as well as supplied externally to international partners in Japan, Korea, and Europe. We produce nearly 20 million yards of the material each year with astounding quality consistency to deliver impressive performance.

Environmentally friendly differential dot lamination using solvent-free laminating adhesives allows the material to remain soft and highly permeable. Polyspun offers a wide range of laminating stencils and adhesive combinations for different fabrics to meet the physical requirements of various laminating products.

For high lamination fastness and resistance to peeling, Polyspun offers a full range of laminating technologies, especially for high-denier fabrics and equipment, to maintain stability and high performance.

-Full Lamination

-Spot lamination

-Matrix-based films

-Polyurethane (hydrophilic, Microporous, Electrospun),

-Thermoplastic polyurethane, Polytetrafluoroethylene, Thermoplastic polyester, Polypropylene

Film production

-Water-friendly polyurethane

-Micro porous polyurethane

Membrane lamination

-ePTFE polytetrafluoroethylene

Our heavy-duty calender uses Taiwan- and European-made machinery to produce high-density nylon taffeta fabric at 10D-30D, compliant with international textile standards. Our annual calendering capacity is 6 million yards.

Whether it is relief printing, antibacterial printing, or customized patterns and colors, GFUN offers one-stop processing to complete production on-site after the printing process. The annual production capacity for this category is 10 million yards.

A wide range of coating technologies to enhance the water repellent effect and functional strength of our fabrics

-Hydrophilic PU

-Microporous PU

-Solvent Based

-Solvent Free

-Bio-based

-PET

The combination of high-resolution color cameras with the latest image acquisition technology is our QA solution to get rid of vibrations generated during traditional walk-and-stop imaging QA, allowing for image detection capabilities of unparalleled precision. The QA system is equipped with a high-accuracy defect classification technology accessible through optimized software and hardware user interfaces that can be intuitively managed. It is further enhanced with AI classification, categorization, and recognition technologies that are also integrated with various communication protocols and manufacturing execution systems to actualize smart manufacturing. Our sewing process is also backed by high-precision machinery that responds to real-time sewing speed updates and defect feedbacks reported by the high-accuracy camera. The data is processed by our central server through its I/O channel to monitor and control voltage stability, heat dissipation, and the high-lumen linear LED lighting system, bringing us one step closer to realizing the vision of smart manufacturing in the age of Industry 4.0.